Editor Andrew Drwiega in conversation with Eric Ditmars, vice president, Secure Sensor Solutions at RI&S, on the eve of the ADEX Korean Airshow.

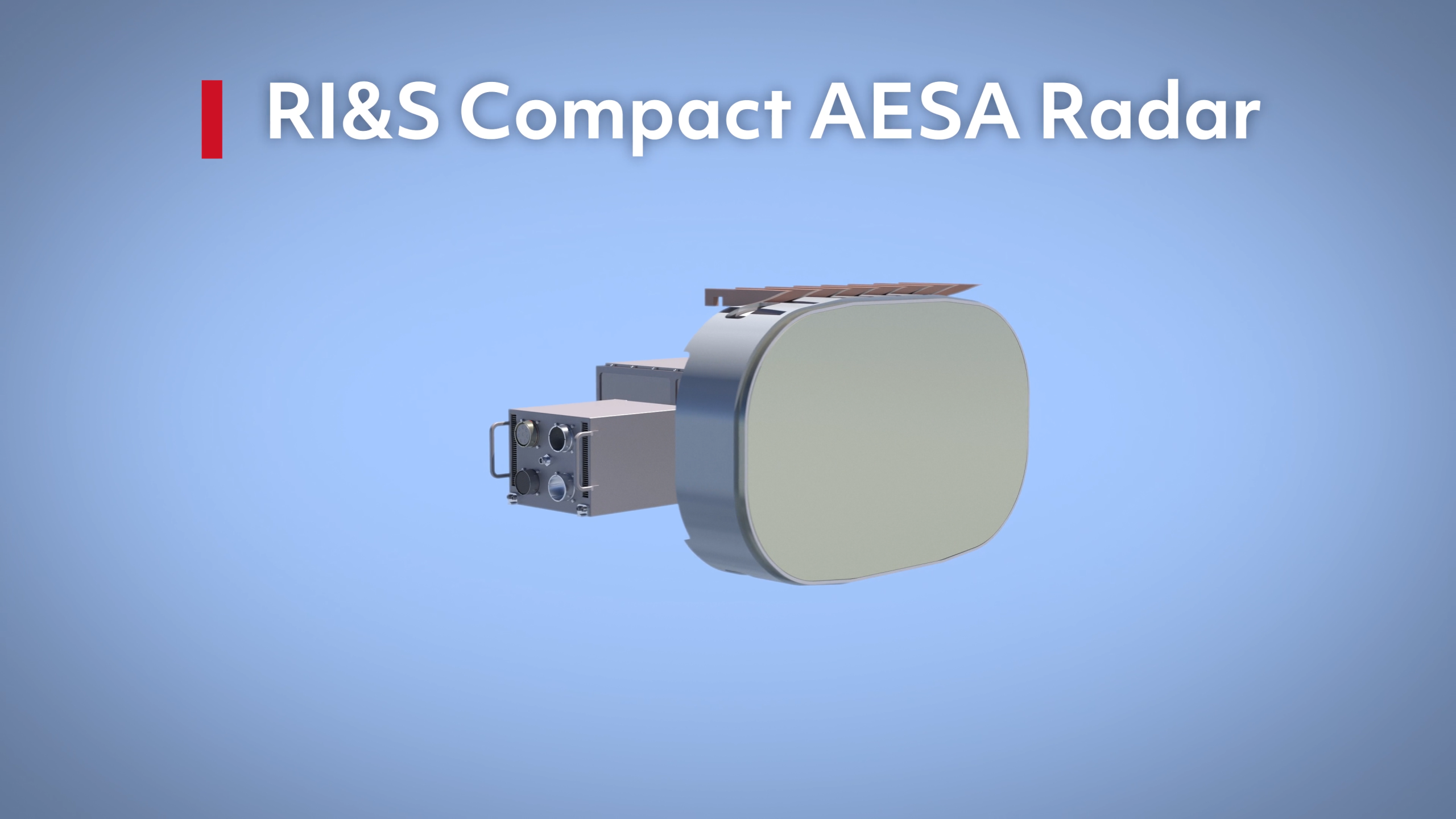

With the wide adoption of Active Electronically Scanned Array (AESA) radars into military aircraft, Raytheon Intelligence & Space (RI&S) has scaled all the capability of its existing AESA radars into a new compact version that offers the same performance but at around half the cost.

“This is a lightweight radar but with heavyweight performance,” said Eric Ditmars, vice president, Secure Sensor Solutions at RI&S, speaking to Asian Military Review ahead of the Seoul International Aerospace and Defense Exhibition, 19-24 October, in Seoul, South Korea. “It uses a third less power than a typical AESA radar but delivers the same performance,” he said. RI&S suggests that when compared to bigger AESA radars, it will be available at half the price, one-third the weight and will only use 65 percent of the power required by larger comparable radar systems.

The compact AESA weighs just over 100 pounds (45kg), yet it delivers 100 percent of the capability of the APG-79 AESA radar which is currently installed in the US Navy’s Boeing F/A-18E/F Super Hornet, F/A-18 Hornet and EA-18G Growler.

Consulting with customers, RI&S identified the need for a smaller, yet as capable radar for platforms that were constrained by size, weight and power (SWaP) such as light attack aircraft, unmanned aerial vehicles (UAVs), helicopters and some ground-based defence requirements.

“We have been delivering AESA technology for over 20 years and have delivered over 1,500 systems to customers and logged over one million operational hours across the type; so the development of the compact AESA radar gives us an opportunity to provide users of smaller platforms with the capability and performance that has only previously been available to those larger platforms,” said Ditmars.

“Downsizing was a technology challenge,” continued Ditmars. “As you start downsizing the circuitry, you are still applying the same amount of power in a smaller location which means you need to increase the ability to reduce and remove heat. This led to two solutions: using Gallium Nitride (GaN) requires less power to deliver the same capability. It is a much more efficient material – allowing a reduction in power which then also reduces the heat generated; secondly, the innovative air-cooled method of taking heat out of the array – which is a big deal – eliminates the need for a liquid cooling system, which reduces weight.” Being air-cooled saves weight but still allows the compact radar to deliver Generation-4 performance.

There is an opportunity for larger platforms to use the compact AESA radar – thanks to its weight and cost savings; RI&S will size the array based on the space available. “On the US Marine Corps Super Hornet, we have the larger APG-79 AESA radar, due to the extra space that the aircraft offers, but on the legacy F-18C/Ds, which are smaller aircraft, we condensed the size of that array and is in fact why we used GaN technology which still allows the aircraft to deliver the same radar performance but in a smaller footprint with less power.”

GaN is becoming more of a standard across many platforms. In recent years it has been used in Raytheon Missile & Defense’s MIM-104 Patriot surface-to-air missile system. “RMD engineers have developed the circuitry that we are using with the GaN material to get the maximum efficiency possible out of it, which gives us the best performance for any application,” stated Ditmars.

Maintenance of the compact AESA is fairly simple. “There are only three components to the radar: the antenna, the exciter/receiver and the power supply – so there is not a lot to maintain,“ Ditmars said.

In terms of when the compact AESA will be available, Ditmars explained: “We already have the AESA hardware, with additional prototypes coming through this year. Flight testing will occur in 2023, either internally on RI&S’ own testbed or with a potential customer – we’re pursuing several of those opportunities. We expect [production] deliveries to begin in 2024.”

by Andrew Drwiega